Clearance Adjustment on Gorman Rupp Pumps

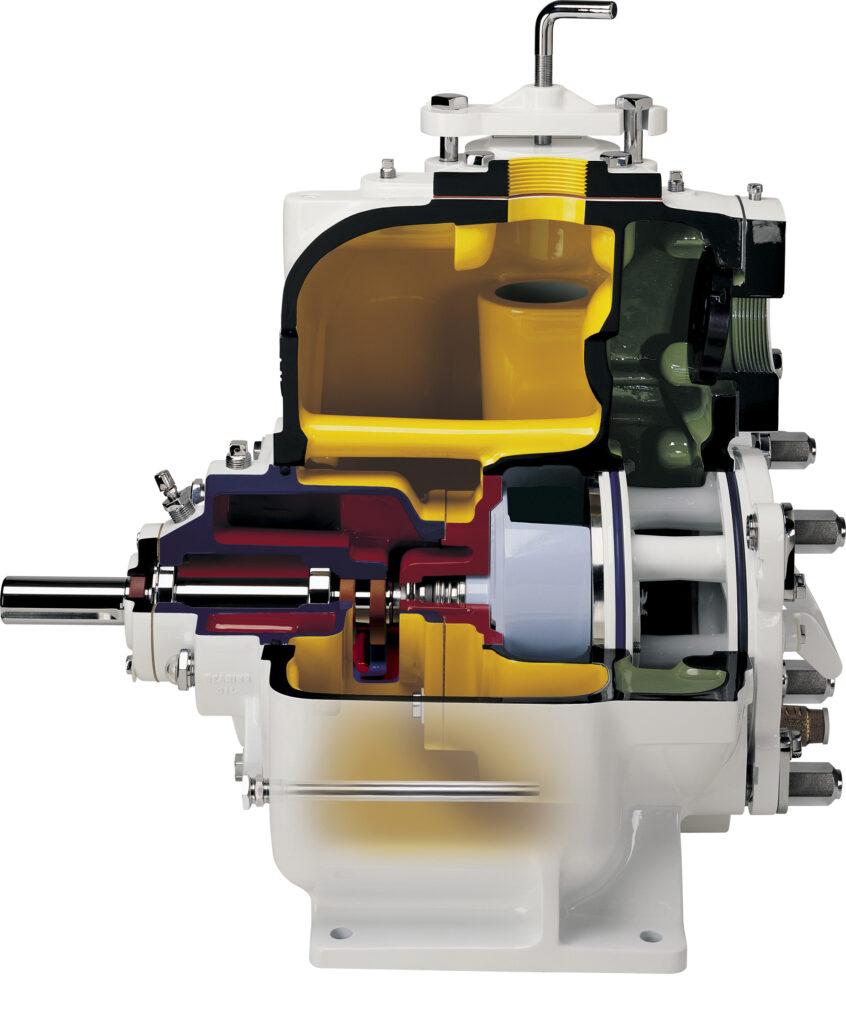

The Gorman-Rupp Super T-Series pumps are crucial in various wastewater applications, from remote pumping stations to sludge pumps at the treatment plant. Regular maintenance, particularly adjusting the clearance between the impeller and the wear plate, is crucial for ensuring longevity and optimal performance. Here’s how to perform this adjustment effectively.

Why Adjust Clearance?

- Improved Efficiency:

- Correct clearance ensures optimal pump performance. It directly impacts flow rates and head pressure.

- Adjusting the clearance maintains efficiency, preventing energy wastage.

- Reduced Wear and Clogging:

- Proper clearance extends the life of critical components like the impeller and wear plate.

- It minimizes the risk of clogs caused by excessive wear or misalignment.

How to Adjust Clearance

Adjusting the clearance on Gorman-Rupp Super T-Series pumps involves moving the cover plate closer to the impeller. This process is straightforward and offers several benefits:

- Ease of Adjustment: The unique collar and adjusting screw allows for precise, incremental adjustments without the need to realign belts, couplings, or motors.

- No Disruption: The mechanical seal and impeller back clearance remain undisturbed during the adjustment.

- Longevity: This design doubles the life of the impeller and wear plate, ensuring the pump operates at maximum efficiency and reduces clogging.

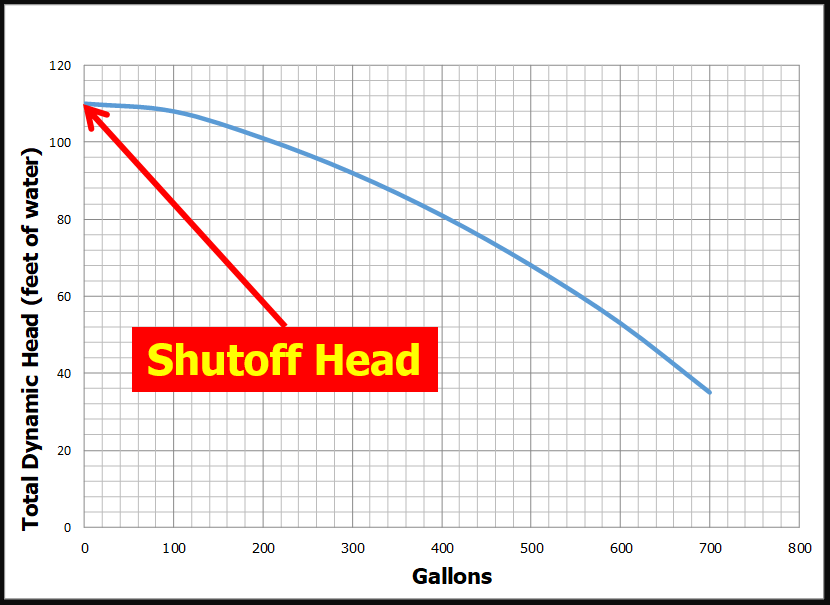

Performing a Shut-off Head Test

A shut-off head test is the best way to determine if the pump clearances need to be adjusted. The shut-off head is a pump’s maximum pressure at zero flow. Slowly closing the discharge isolation valve while the pump is operating will increase the pressure in the discharge line, and the pump will eventually reach its shut-off head pressure.

Comparing the discharge gauge readings to the shut-off head pressure when the pump was new is an excellent way to determine if the pump clearances need adjustment. If the shut-off head pressure is less than 5% of the original shut-off head pressure, it indicates that the internal clearances in the pump have increased due to wear or other factors.

Conclusion

Maintaining proper clearance is vital for the efficiency and longevity of your Gorman-Rupp Super T-Series pumps. Regular adjustments and shut-off head tests ensure your equipment operates at peak performance, minimizing energy wastage and extending the life of critical components. Contact Envirep, your local Gorman-Rupp representative for expert assistance and sales inquiries.

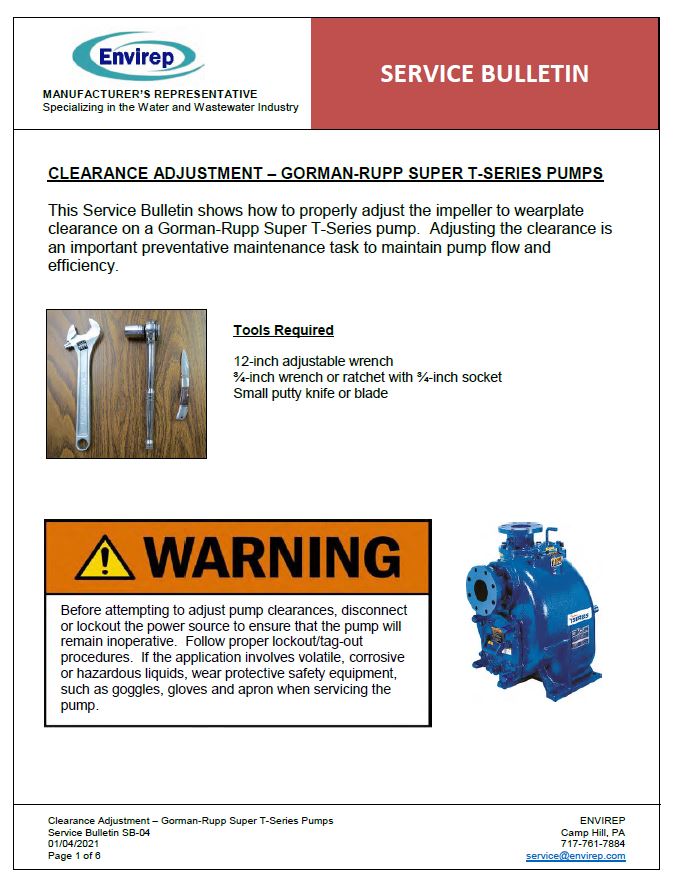

For detailed instructions, refer to our Service Bulletin.

CLICK HERE to see our other manufacturers.

CLICK HERE to learn more about Gorman-Rupp Super T-Series Pumps.

By Dwight Swan, Sales Engineer at Envirep/TLC

Gorman-Rupp is the industry leader and innovator in high-quality pump design. At Envirep/TLC, we will help you choose the best Gorman-Rupp® pump parts for your needs. We aim to provide you with easy-to-operate, low-maintenance pump parts to ensure you areas cost-effective as possible.

Envirep/TLC is an authorized distributor of Gorman-Rupp pump products.

When repairing a Gorman-Rupp pump, it is always best to use genuine Gorman-Rupp parts. Gorman-Rupp builds their parts to exact tolerances and exact material specifications. Not having the right part can reduce the service life and affect the pump’s life and efficiency. Only genuine Gorman-Rupp parts can guarantee that your part will fit perfectly and deliver reliable service for many years.